An high performance and innovative tool

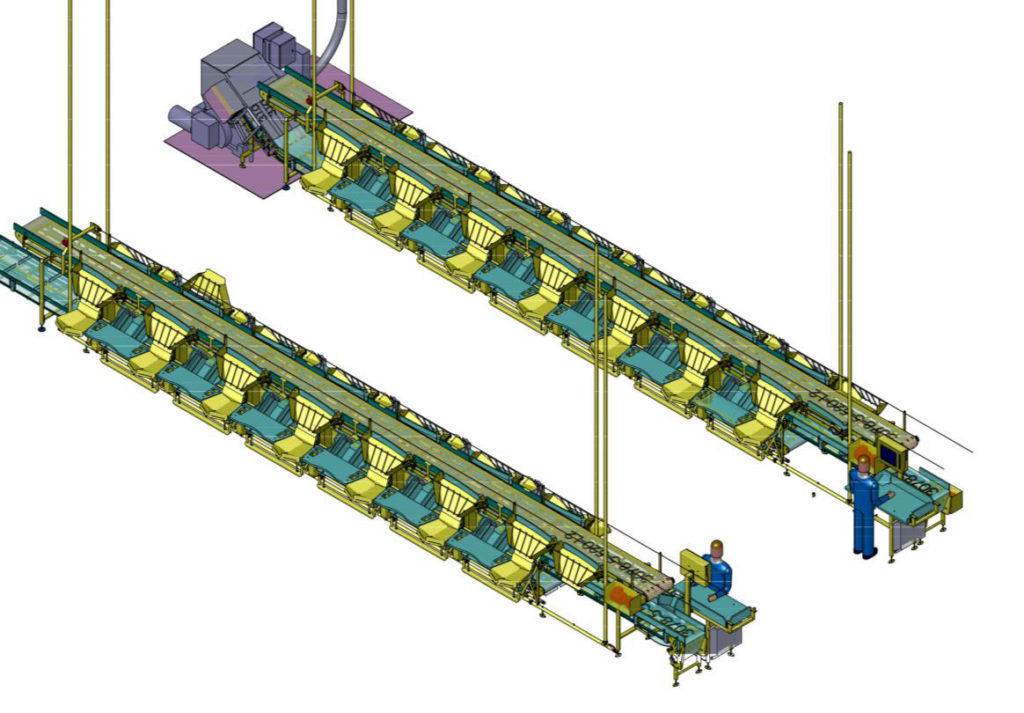

Calibra SL Station Line is a smart slaughter line. Which allows the realization of de-boning/cutting operations per work station. The objective is to handle products supplying for each operator work space directly from a computer. This process is the best way to minimize issues related to products coming to fast or too slow and prevent delays in products treatment. It also enhances implementation of the working space and limit the handling of products by operators.

This system is an innovation in turkey domain more specifically cutting legs operation. Each line allow the distribution of entire turkey legs at a given limited rate per workstation (number of products/given time) and to retrieve noble pieces from secondary products and remains.

Each boning station can be set by the operator with a manual pneumatic system (up/down)

Productivity and material yield

Products from de-boning/trimming operations are distributed at a stable throughput. Which can be set regarding your operators specificity (right or left handed, new or experimented,…).

The up and down pneumatic system reduces efforts made by your employee at each work space. Enhancing overall ergonomics and reducing MSDs.

Collection of boneless products toward packaging lines is automatized, limiting handling by operator and reduce incident risks related to space organization.

Ergonomically designed and individualized

Each work space is individualized. Deboning and cutting tables are designed for each operator specificity such as left or right-handed .

Work spaces can be adjusted in height by the operator with a pneumatic system. An indicator on the side indicates at which heights it is set.

This system reduces considerably MSDs at work.

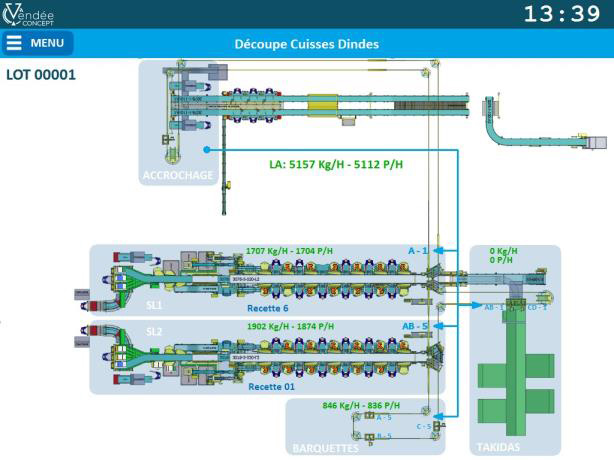

Brand new User Interface (UI)

Our brand new User Interface designed by our IT engineers has been thought around and for you. It make the setting of our industrial range of products easier.

Creating a new program is simple, fast and intuitive. So the person responsible of the line will save a lot of time about which settings he could/should use.

Computing system of the CALIBRA SL allows productivity control and material yield. Each line is equipped of a control system in order to realize some random quality test to maintain the required quality level.